Endoscopic Sensor Bridge

Endoscopic Sensors

Endoscopic sensors play a pivotal role in modern healthcare engineering by enabling minimally invasive procedures, thus revolutionizing diagnostic and therapeutic interventions. These sensors facilitate precise imaging within the body, allowing healthcare professionals to visualize internal organs and tissues without invasive surgery thanks to endoscope cameras. This minimally invasive approach reduces patient discomfort, shortens recovery times, and lowers healthcare costs.

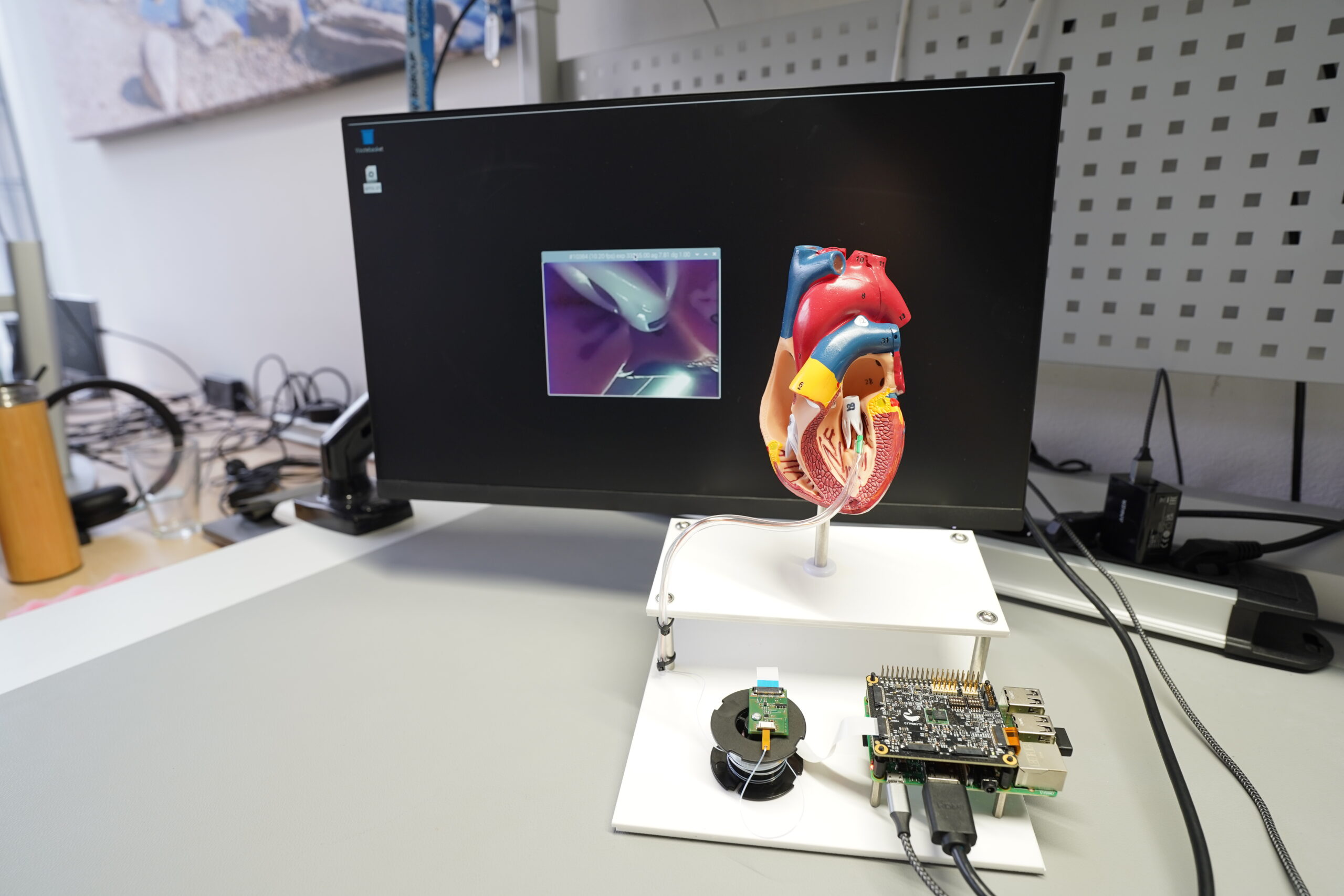

Endoscopy proof of concept demo

Medical endoscopy applications encounter specific design limitations. Being specialized embedded vision applications, they commonly face challenges such as the requirement for flexible sensor cables and compact image sensors. These thin and malleable sensor cables are essential for delivering power, video transport, and managing a control interface, highlighting the necessity for a standardized electrical interface tailored to specific requirements. Conventional application processors used in endoscopy instruments lack the native capability to receive video data from these specialized image sensors. Consequently, a Video Bridging Module like Citrobits CBM100 helps to optimize and expand the capabilities of an embedded vision-optimized FPGA, such as the the low-power Lattice CrossLink-NX FPGA, providing an optimal solution for addressing these unique application scenarios.

The ASM Osram endoscopy sensor its connected to one meter long tiny ribbon cable that has four signals in it. That goes to a interface board that provides mechanical connections and signal conditioning over to the Citrobits CBM100 Module that holds the Lattice FPGA and allow these connections.

This NanEyeM Osram image sensor special interface has a single interface mode for configuring the sensor and LVDS for the actual image transfer, all happening just over two wires. The Citrobits Video Bridge EVA NEYEM01 evaluation board is providing bridging function within the CrossLink NX FPGA, from the sensor to a MIPI interface to a host processor. Inside the FPGA we can do other things like ISP, or sensor stitching. It can stitch together multiple sensors for AR/VR or video aggregation applications inserting Videos IDs into the video stream itself.

FPGA Video Bridge Module

Introducing our technology demonstrator, poised to simplify sensor interfacing in the digital era. Harnessing the power of Field-Programmable Gate Arrays (FPGAs), our module seamlessly bridges native Low-Voltage Differential Signaling (LVDS) from Optasensor and AMS Osram sensors to the universally adopted MIPI CSI2 standard. This innovation streamlines connectivity between sensors and System-on-Chips (SoCs), enabling effortless integration into a wide array of applications. By providing a robust, FPGA-based solution, we offer unparalleled flexibility and efficiency, empowering developers to optimize performance and accelerate time-to-market.

Unveil the future of sensor connectivity

Ready to deploy solution. pre-programmed devices with minimal physical footprint.

Reduce power consumption running image processing directly on FPGA fabric.

Deterministic data processing offloading computations from external visualization devices.

Built-in update mechanism for on-the-field upgrades and firmware updates.

AI-ready for automatic image processing and quality enhancement.

Minimal size and weight for handheld devices.

Key Benefits

- Signal Translation: Effortlessly translates native LVDS signaling from sensors to industry-standard MIPI CSI2, ensuring compatibility with a wide range of System-on-Chips (SoCs) and other devices.

- Seamless Integration: Facilitates seamless integration of sensors into existing systems by providing a standardized interface, simplifying development and reducing time-to-market.

- Enhanced Performance: Leveraging FPGA technology, the module offers high-performance signal processing capabilities, enabling real-time data transfer and processing with minimal latency.

- Configurability: Provides configurable logic within the FPGA, allowing for custom adaptations and optimizations tailored to specific application requirements, enhancing flexibility and performance.

- Reliability: Ensures robust and reliable operation, critical for mission-critical applications in healthcare, industrial automation, automotive, and beyond.

- Future-Proofing: With reconfigurable logic and scalability, the module offers future-proofing capabilities, accommodating evolving technological needs and ensuring long-term usability and compatibility.

- Power Efficiency: Optimized for power efficiency, the module minimizes power consumption while maintaining high performance, making it suitable for battery-powered or energy-efficient devices.

- Rapid Deployment: Streamlines development cycles with rapid prototyping capabilities, accelerating the deployment of sensor-based systems and reducing development costs.